10 tools to start on your DIY journey

One of the things that can feel overwhelming when it comes to being a beginner DIYer is not knowing where to start when it comes to those first tool purchases. Whether it’s not knowing which tools to get first, or what brand to go with, or what accessories to get, the world of tools is one that you’ll need to enter in order to have success with your DIYs!

Another big reason it can feel overwhelming: money. Tools cost money! And some of them can be more expensive than others. Don’t feel like you need to run out and buy a whole workshop full of tools right of the bat. You can buy tools slowly, as you need them.

We’ll start with some non-power tools that I always keep on hand, and then we’ll get into the power tools that are essential!

Hammer

This almost feels like it goes without saying! A hammer is one of the most basic tools out there and it’s extremely handy. A hammer is great for everything from putting up shelves and building Ikea furniture, to framing a wall. There are lots of hammers out there, but a basic standard hammer is all you really need (unless you start getting into some more specific building realms). And! They’re very inexpensive.

Tape Measure

”Measure twice, cut once!” and in order to measure twice, you’ll need a Tape Measure. You may want multiple, because if you’re anything like me, you’ll misplace yours and there’s nothing more annoying than not being able to find a tape when you’re working. I also keep a smaller 12 or 16ft tape in my house for easy grabbing, and I’ll usually have a 12ft one in my purse for when I’m out and about and need to measure furniture or stuff at Home Depot. A standard 25ft one is a really great length for having in your toolbox, and is what I have in mine!

Level

A level is super handy and the type you get first may depend on what you’re most wanting to do, DIY-wise. If you’re just installing shelving, hanging pictures, etc— smaller stuff, you may only need a short little level. If you’re leveling counters, floors, or larger projects, you’ll probably want a larger one. I like having a small 1ft level for little things, a more substantial 4ft level, as well as an 8ft one. If you want to get techy and fancy you can also get a laser level, which is a very cool little tool!

Sawhorses

Havinga set of sawhorses, even just some cheap plastic ones, comes in SO handy when you’re working on projects. Cutting wood, making a makeshift table, painting things, sawhorses will help with countless projects and make things 100 times easier.

Power Tools:

Power tools come in two options: corded and battery powered. Typically corded versions are a little more affordable, and they can also be more powerful, but cordless battery operated tools can be more lightweight and convenient. For instance, my battery operated brad nailer is WAY more convenient because I don’t have to hook up my air compressor and pull out the long air hose. I just pick it up and start nailing. My battery operated circular saw is also much lighter and easier to wield than my corded version, but the corded version is more powerful.

Another thing to consider if you start buying battery powered tools is that you’ll want to stick to a brand, only because once you start buying batteries, those batteries will be specific to that brand’s tools and won’t work on another brand. So you don’t want to buy a Ryobi drill and get the battery pack and charger for that and then get a Makita circular saw, because then you’ll have to invest in Makita batteries and charger (and batteries can be expensive!). So stick to one brand, get a few batteries so you can have a spare or two on hand, or charging up so you’ll never get stuck with a tool and a bunch of dead batteries mid-project— that’s the worst!

This obviously doesn’t apply to corded tools since their power source will be the outlet, so you can go “off brand” with those. I use Ryobi for my battery powered tools and I have a few random brands in my corded tools.

Brad Nailer

Having a brad nailer is super handy for a lot of different projects. Working on furniture, installing trim, putting up molding, making shelving, my brad nailer gets a ton of use around my house. There are lots of different nailer types and sizes too, so depending on what projects you think you’re most likely to tackle, you may want a stapler, a pin nailer, a 16 gauge, etc. I LOVE having a battery powered nailer because then I don’t have to have an air compressor with a long air hose dragging through my house in order to work on projects.

Drill + Impact Driver

A drill is one of the most useful and basic power tools you can have in your arsenal. Not only can you drill various size holes with standard drill bits, spade bits, hole bits, and more, you can also use it as a power screw driver. I would say that my drill is my most used tool over the years and if you don’t have any tools at all start with a power drill! An impact driver is very similar to a drill and they look almost identical, but there are some differences. Impact drivers are more lightweight and compact and they also have more torque. While drills hold bits using a “chuck” which is basically a unique way to clamp down on the bit to hold it in place (and you can use standard or hex bits), Impact drivers have a quick change clamp and only take hex bits.

So why/when do you use an impact driver? Impact drivers are more commonly used to drive in a large quantity of fasteners, longer screws and lag bolts. If you use impact-rated, 1/4-inch hex-shank drill bits, you can accomplish some basic drilling tasks with an impact driver. However, these tasks will be limited in scope. An impact driver is not ideal for precision drilling tasks and should be limited to jobs where the size or placement of the hole is not crucial but more torque may be needed, such as drilling through metal and dense or knotty wood.

A lot of time you’ll see these two sold in a set, which is a nice way to get both, but if you can only afford one, go with a standard drill. I will add that driving in screws is much easier with an impact driver, and as a small (yet strong) woman, I have to use much less force to screw in using an impact driver, which is nice.

Circular Saw

The circular saw is an extremely useful tool if you’re doing any kind of building. It’s the first power saw you should add to your toolkit, IMHO. You can make cross cuts, rip cuts, angled cuts, and more. It’s great for cutting plywood, lumber, you can use a blade designed to cut metal, etc. It’s a super handy tool that will instantly level up your DIY. A circular saw can feel intimidating to some, so make time to practice to get the feel for and hang of how it behaves and cuts.

Jig Saw

The one big limitation that a circular saw has is that it can’t make curved cuts. Which is why I highly recommend grabbing a jig saw next. After my circular saw, my jig saw is my most used saw. I love it’s capabilities, and it’s the pervect tool for making more precision cuts.

Sander

Having a power sander on hand is super useful. I use mine all the time. Whether I’m sanding down a piece of furniture to refinish, prepping cabinets to paint, cleaning up cut edges, or smoothing rough surfaces, my sander makes it so easy. There are a few different style of sanders, but for starting out I’d get a sheet sander, or orbital sander, though a corner sander is also a great starter. These styles are great for most basic sanding you’ll be doing.

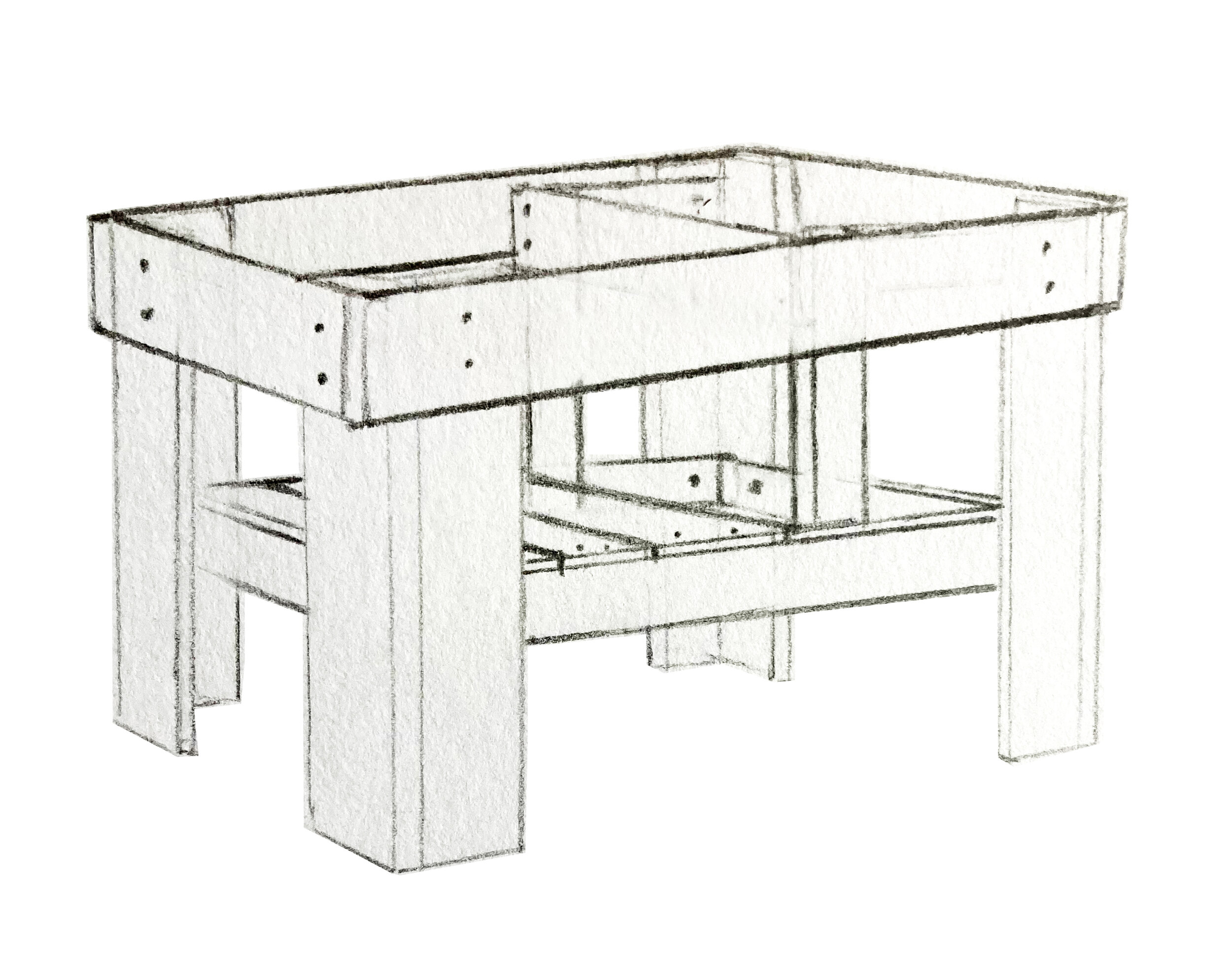

DIY Fireside Cooler Table Tutorial

There’s not much I love more than enjoying a cold beverage while sitting beside a campfire. We’ve been needing a side table for our fire pit area for a while now, so instead of building a regular table, I made one that houses our little cooler! Now we can have ice cold bevs on hand while we’re enjoying the backyard!

Want to build your own cooler table? Just follow the tutorial below!

You’ll need:

A cooler

Drill

18 gauge brad nailer

Cedar 1x4s

1x2s

Cedar fence boards (lumber quantities will depend on the size of the cooler you’re building the table around)

2in exterior screws

1 1/4 in exterior screws

3/4 in screws

Flat metal plates

Small hinges

Step 1:

Make the corner uprights

Cut your cedar 1x4s into eight 22in lengths (or longer if you want your table higher). These will be the corners of your table. Drill pilot holes and then screw them together in an “L” at a right angle using 2 in exterior screws. I put 3 screws in each.

Step 2:

Make the basic structure

Attach 1x2s to the corner pieces to connect them all together. This will be what the platform for your cooler sits on, so you’ll want to measure the height of your cooler, and then add a half inch— that’s how far down from the top of the corner pieces you’ll attach these 1x2s. The length and depth of your table will depend on the size of your cooler. I’d measure the short side 1x2s to be about an inch larger than your cooler’s depth. If you want to have a table section that doesn’t open (like mine), measure the width of your cooler and add about 10-12inches. This will how long you want your long side 1x2’s to be. Drill pilot holes in the 1x2s before screwing them to the corner pieces and then attach wth 1 1/4 in exterior screws.

Step 3:

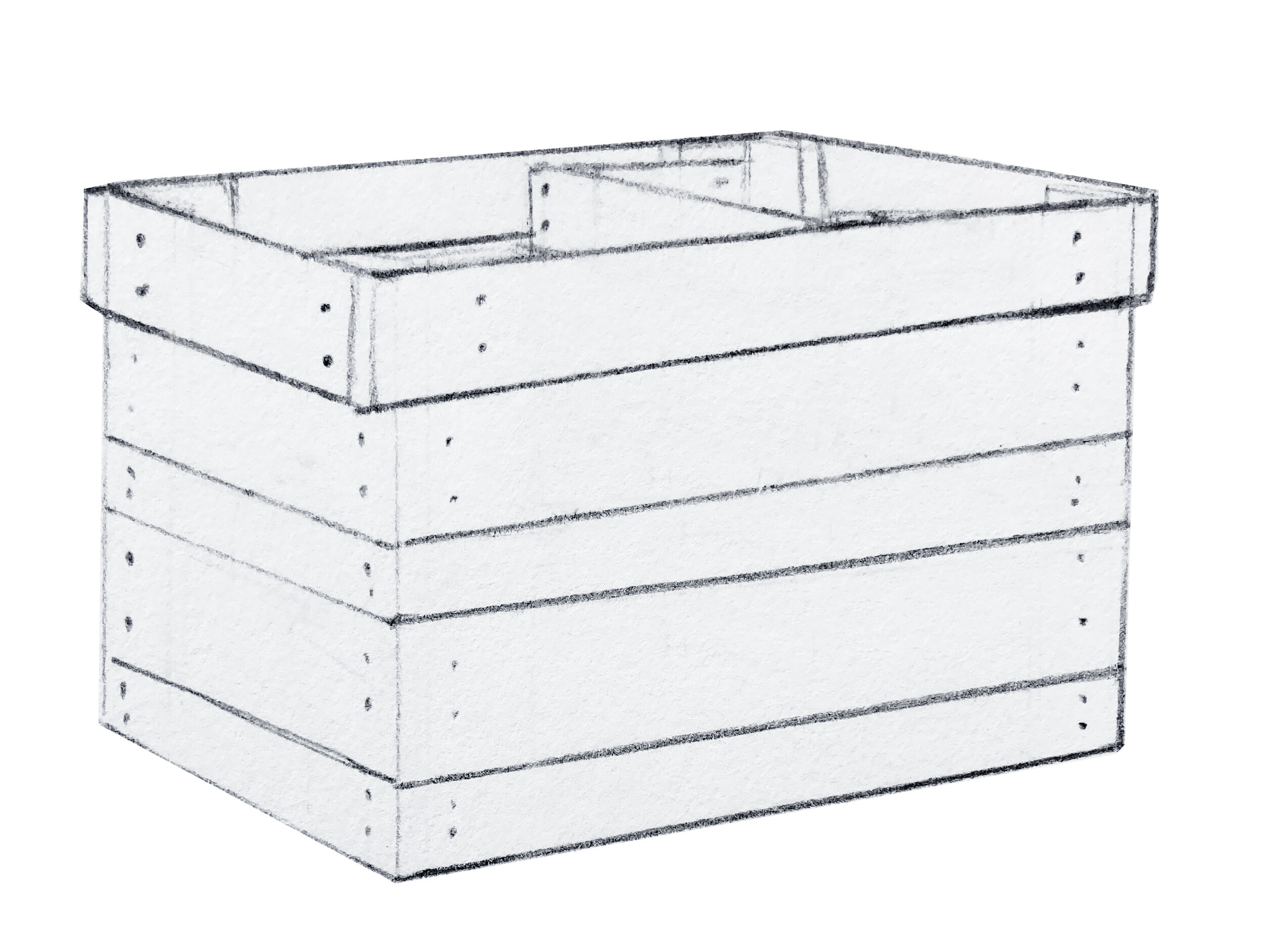

Create the platform for the cooler

Cut cedar fence board that span across and rest on top of the 1x2s. This will be the platform that your cooler sits on. Use an 18 guage brad nailer to attach the boards to the 1x2’s

(image is viewing from the top down)

Step 4:

Create an interior wall to secure the cooler

This step is probably unnecessary, but I wanted to create a little barrier so the cooler didn’t scoot over under where the table top doesn’t hinge open. This just keeps the cooler snug in it’s spot. I did this by framing a barrier using 1x2s (which is what I had on hand), but you could also just add another cedar 1x4 to the outside of the platform base 1x2s and then do a cedar fence board across the top from front to back.

Step 5:

Wrap the top of the table

Measure the short side of the table from corner to corner, then cut two cedar 1x4’s at that length. Attach to the top of the corner uprights using 1 1/4 in exterior screws or 18guage brad nails (if you don’t want to see the screws). Do this on both short sides. Now measure the long sides, including the pieces you just attached. Cut two lengths of 1x4 at that measurement and attach those to the long sides of the table.

Step 6:

Sheath the outside of the table

Using cedar fence boards (I used both 5.5in wide and 3in wide fence boards) repeat the process you just did for attaching the 1x4s to the top. Use an 18 gauge brad nailer to put two nails in each side of each board to attach them to the corner uprights. I put a small gap between each board (the width of a carpenter’s pencil).

Step 7:

Create the table top

The table top is made out of cedar 1x4s. I had my table top over hang about a half inch on either side, so my 1x4s were cut 1 inch longer than the depth of the table. For the side that isn’t hinged, you just attach the 1x4s to the base. You can do this with brad nails from the top, or if you don’t want any fasteners showing on the top (which I didn’t), you can use pocket screws to screw the table top boards on from below.

I used flat brackets and 3x4in screws to attach all the hinged table top boards together, which is a bit inelegant, but works great. You could also use pocket screws to screw the boards together side by side.

Once your hinged table section is created all you have to do is attach it to the base using a couple small hinges!

DIY Painted Faux Tile Backsplash

My ultimate plan for our kitchen backsplash involves a gorgeous black zellige tile, but I knew that it would be a while until we got that tile project underway. In the meantime, I decided to have fun with a hand-painted backsplash that gave the effect of a faux tile look. I absolutely love how much depth the dark backsplash adds to the space!

Hand painting isn’t for everyone and there are other affordable but less tedious and time-consuming ways to upgrade your backsplash, like stick-on tiles, removable wallpaper, and paint stencils. You can even get a stencil that mimics this hexagon design!

For my process, I used chalk to trace the hexagon shape onto the wall, then used a straightedge to draw the lines inside the hexagons with chalk. Once that template was on the wall, I used a small craft paintbrush to paint interior latex paint along those lines. Definitely tedious! But I did this in the midst of the post-election madness and a tedious project that needed a lot of focus what a pleasant distraction, haha.

DIY Hanging Rope Shelf

I made this shelf probably five or six years ago and it’s followed me around in all those years. I brought it over to our new house when we moved in last year and it’s just been sitting in Jack’s closet since then. Yesterday I finally decided to put it up, but then when I got some questions about it I realized I had never posted the DIY to my blog! So here it is!

What you’ll need:

Rope

Screw hooks and anchors

Wood planks

Drill

1/ Drill holes in the shelves in their four corners, about an inch in from the edges.

2/ Decide how far apart you want your shelves to hang from eachother. Cut a length of rope long enough to go from the bottom of the lowest shelf, up to the top of the shelves and back to the bottom, plus a couple of feet.

3/ Tie a knot at one end of the rope and push the other end through a corner hole on the first plank. Tie the next knot at the distance apart you decided to make your shelves and then push the end of the rope through the next shelf’s corresponding corner hole.

4/ Repeat with each shelf. When you reach the top shelf, create a looped knot at the top, forming a right triangle so the shelves hang level from the screw hook you’ll be hanging the shelves from.

5/ Now, take the rope down through the back holes in the shelves, tying knots at equal distances as the first set of knots so the shelves hang level. When you get back to the bottom knot, cut off the excess rope. Repeat with the second side.

6/ Measure the distance between the two rope sides to determine how far apart you’ll place your hooks. Decide how high you want the shelves to hang, then install your screw hooks. You might want to put anchors in, depending on what kind of walls you have and how heavy you predict the items on your shelf will be.

7/ Once the screw hooks are in, you can hang the shelf! Use a level to check that your shelves are straight. You may need to do some tweaking and raise/lower some of the knots to get everything perfectly level.

DIY Minimal Scandinavian Slatted Headboard

When we moved into the flip house, we left pretty much all our furniture at the other house so it could be a fully furnished Airbnb. We ended up getting an old Ikea Hopen bed frame for free from a friend who didn’t need it anymore, but I knew I wanted to replace the headboard with something unique and more scandinavian-inspired. I’d seen a slatted Ikea headboard before, but upon some research found out it was discontinued, so I set out to make my own! I figured it’d be pretty simple since it was just wood slats, and it was!

What you’ll Need:

12 8ft 2x2’s

2-3 8ft 1x2’s

1.5in wood screws

If you want to make this very affordably, get 2x2 furring strips. They’re usually under $3 each, but furring strips are made of pretty low quality wood, so you’ll need to dig through them to find ones that aren’t warped, cracked, or with a bunch of knots. If you want fancier wood, you can find pine 2x2s in the trim section that can be more like $11-12 each. I wanted to make this on the cheap so I opted for the furring strips.

Depending on how wide you want your headboard, you may need to cut the 1x2’s down. I wanted mine to be 8ft so I didn’t need to cut my 2x2s shorter.

Cut your 1x2s down. I cut mine down to 3 ft so they would stick down below the slats about 6 inches and sit behind the back of my bed frame between the frame and the wall to keep the headboard in place. I kept the middle three 1x2s 3 ft long, and trimmed the ones closest to the end on each side down so those two didn’t stick out below the bottom slat. If you don’t have a bedframe where this method would work, you can cut the middle 1x2s so they go from the top of the headboard, all the way to the floor, appx 44in.

If you want the 1x2 verticals to disappear more, you can paint them the color of the wall behind your headboard before attaching them.

3. Lay out your 2x2s how you want them for your headboard and make sure the ends are all even. I spaced them out about 3/4 inch, using a piece of 1x2 to space the 2x2s evenly.

4. Once all the 2x2s were set up, I placed my 1x2s on top, starting with the one right in the center, then spacing the others 18 inches apart. I used pencil to draw a line along each side of each 1x2 marking where they went (in the illustration I drew four 1x2s, but I realized later that I actually used five).

5. Start by screwing the two outside 1x2s onto the 2x2s. I’d recommend pre-drilling the 1x2s, as I was lazy and didn’t and had a bit of splitting on a couple of my 1x2s. as I was screwing, I put the spacer 1x2 between the 2x2s as I was screwing to make sure they were spaced exactly.

6. With the two outside 1x2s attached, the spacing will be set and you can screw the remaining three 1x2s on, and you’re done! Flip it over and put it behind your bed! I didn’t anchor mine because it’s pretty well stuck between my bed and the wall, but you can also screw the 1x2’s to the wall between the slats in a few spots to make sure it stays put.

More DIY this way….

Hi, I’m Liz

I'm an artist, writer, designer, DIY renovator, and … well basically I like to do all the things. If it’s creative I’m probably doing it. I’ve spent over 30 years voraciously pursuing a life steeped in creativity and I wholeheartedly believe creativity and joy are inextricably linked.

Read more…

Explore The Archive

- January 2026

- July 2025

- May 2025

- January 2025

- December 2024

- August 2024

- July 2024

- May 2024

- April 2024

- January 2024

- December 2023

- October 2023

- September 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- August 2022

- June 2022

- May 2022

- April 2022

- March 2022

- November 2021

- October 2021

- August 2021

- July 2021

- May 2021

- January 2021

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- February 2020

- January 2020

- November 2019

- October 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- February 2018

- January 2018

- November 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

VISIT THE SHOP

PRIVACY POLICY & DISCLOSURE

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.